Biocarbon is Carbon.

Carbon is a valuable Commodity.

We can help you refine Carbon from Biomass.

Biocarbon refining is a transformative opportunity for industry to replace Fossil Carbon with sustainably produced Biogenic Carbon via Biomass Refining.

Biomass Refining takes a sustainable “waste” material such as Biomass and uses Pyrolysis to transform it into Biocarbon, Bioliquids, and Syngas. For every 4 tons of Biomass pyrolyzed, a sophisticated pyrolysis system is capable of producing the following:

1 ton of Biocarbon @ 85%+ Carbon

1.2 tons of Bioliquids (a mixture of water, wood vinegar, and oil)

2.0 Carbon Dioxide Removal Credits (CORCs)

Syngas capable of generating ~2.55 MWh of Electricity

In addition to the economic value of the above items, the following are a few of the benefits of Biochar and BioCarbon:

Biochar:

Increases carbon content of soil

Enhances water holding capacity of soil

Can absorb and slowly release fertilizers, helping to prevent excess runoff or release of fertilizers into the environment

Acts as a habitat for beneficial microbes

Can filter out toxins from water

Biocarbon:

Can be used in metallurgy as a reducing agent replacing coal coke

Can be valorized into Carbon Black, Graphite, and Activated Carbon

Used in industrial products such as polymers, asphalt, pigments, and is being explored as a carbon negative additive to cement and other building materials

How Can We Help You Today?

Carbon Refining:

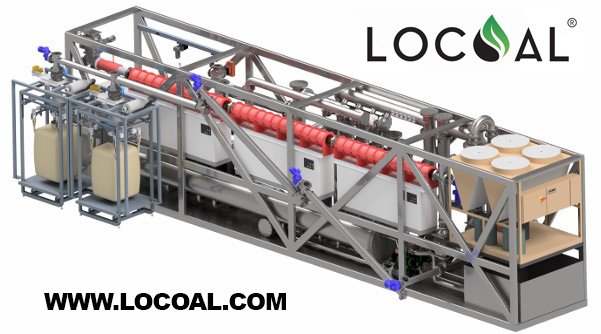

BioCarbon Services is pleased to represent LOCOAL® and their U.S. designed and manufactured Rainmaker™ Pyrolysis system. A Rainmaker™ can be used to create premium Biochar and Biocarbon, generator-ready Syngas, and the life-cycle assessment (LCA) data necessary to generate Carbon Credits from waste-wood and biomass. There is no finer way to refine Biocarbon. Please write us for more information at info@biocarbonservices.com

Let’s chat about Carbon:

Biochar and BioCarbon are both Biogenic Carbon materials refined from Biomass via Pyrolysis. BioChar often has lower carbon concentrations varying from 10-75%. BioCarbon typically has a Carbon concentration higher than 75%. Biochar is excellent for use in agriculture. Biocarbon, because of its purity, is perfect for use in industrial processes such as Metallurgy (e.g. iron ore purification) and as an industrial ingredient where high-purity carbon is required. Both materials are commonly sold by volume (by cubic yard) and by the Ton. If you need help with the math check out our Blog post on the topic of Units of Measure. There you will find a useful Excel tool to help you calculate price per cubic yard or short ton based on density, moisture content, and carbon content.

BioCarbon vs Biochar?

If you heat biomass up to ignition temperature (480-640 F) in the presence of oxygen it will burn (an oxidation reaction where the carbon in the biomass reacts with the oxygen in the atmosphere creating heat and carbon dioxide gas). If you do this same thing in the absence of oxygen, the biomass won’t burn. Instead the heated biomass will release “Syngas” which is a mixture of mostly Methane with trace amounts of Nitrogen, CO2, Hydrogen, Oxygen, and Carbon Monoxide. The “solid” material left behind is mostly high purity carbon and a small amount of ash (a mixture of calcium, magnesium, potassium, etc.) The process of heating carbon containing materials in the absence of oxygen is called Pyrolysis and the carbon left behind can be described as being Biochar or BioCarbon depending on its purity.

What is Pyrolysis?

Fossile carbon is carbon that has been trapped for millions of years: think coal, oil, and natural gas. The carbon in these materials started out as a part of a carbon containing gas like Carbon Dioxide. Over time, this carbon dioxide was absorbed into plants (plants keep the carbon and release the oxygen). If a dead plant is covered by rock and soil, rather than turn back into a gas, this material can form coal and oil. The coal and oil we use today was slowly formed 200-300 million years ago which is why it is called “Fossil Carbon”. When we burn this coal and oil, we release this trapped carbon back into the atmosphere in the form of carbon dioxide increasing the amount of carbon containing gasses in our atmosphere. Carbon containing gasses contribute to global warming because they act as an insulator around our planet. Our planet needs carbon dioxide in the atmosphere, just not too much.

What is “Fossile Carbon”?

Biogenic carbon is the carbon which is around us every moment of every day, often in living things, and is part of the “natural carbon cycle”. Biogenic Carbon often starts out as a gas like Carbon Dioxide. The plants in our yard absorb this Carbon Dioxide, keep the carbon, and release the oxygen back into the atmosphere. If this plant rots or burns, the carbon will reenter the atmosphere as methane or carbon dioxide and stay there until it is absorbed into a new plant. Instead of letting a plant rot or burn, you can refine (isolate and sequester) the carbon using pyrolysis. Isolated carbon refined via pyrolysis is called Biochar or BioCarbon. For carbon credit purposes, carbon is considered to be “sequestered” and have “permanence” if it remains as carbon for at least 100 years (ideally far longer).

What is “Biogenic Carbon”?